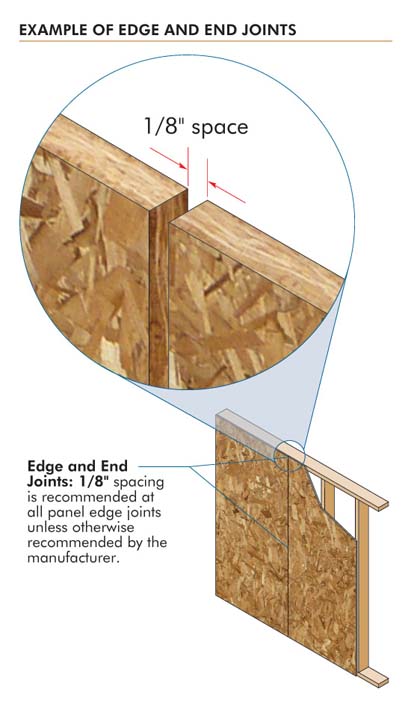

Like all wood products, plywood and oriented strand board (OSB) will expand or shrink slightly with changes in moisture content. If wood structural panels are tightly butted, leaving no room for expansion, buckling can occur. While buckling is not a structural deficiency, it may result in aesthetic or serviceability issues, such as the appearance of wavy roofs and walls or uneven floors. This can mean costly, time-consuming callbacks.

To avoid buckling, follow this simple guideline: Install plywood and OSB with a 1/8-inch space between panel edge and end joints. Determining proper spacing is as easy as keeping a 10d box nail handy; slip the nail in between panels, snugly but not forced, and if it stays put, you’ve created the proper gap.

First and foremost, always follow recommendations and installation requirements from the manufacturer for the panels and application you’re installing.

This how-to article is part of the Builder Tips series of publications from APA-The Engineered Wood Association. To view more helpful strategies, visit www.apawood.org/buildertips.

Advertisement

Related Stories

Sustainability

Fortera Takes Concrete Steps to Reduce the Climate Impact of Cement

Clean-tech company Fortera, which uses technology to capture carbon emissions form cement manufacturing, will open its first commercial-scale operation on April 12, 2024, in California

Building Materials

Lumber Leads Building Materials Prices Higher in March

Overall, the cost of building materials rose during March, with softwood lumber, gypsum products, and concrete all seeing price increases. Only steel mill materials saw price drops

Awards

6th Annual Most Valuable Product Awards

Drumroll ... Please join us in celebrating our 6th Annual MVP Awards winners, which represent the best in innovative building products