Excess or unused wood accounts for up to 40% of jobsite waste, according to estimates from the NAHB. Too many builders, contractors and dealers accept waste as an unavoidable consequence of construction and remodeling, with not enough consideration being given to how waste adds to a project’s cost.

Most estimators, for example, are still commonly including an additional 8% to 12% to factor in waste management.

Hauling even a small amount of unused or excess wood back to the dealer yard or to a landfill or recycling center adds up in both direct product costs as well as also in coordination time, and it lowers capacity of the framing crew and the servicing dealer.

Waste is pervasive, but it doesn’t have to be. Here are four approaches to consider that can help reduce the excess that saps framing budgets and schedules.

Plan Ahead

Advanced planning and collaborative communication are the best first step toward limiting framing waste. Although planning ahead happens on nearly every project today, most framing and other trade subcontractors arrive on the jobsite and find that what they were expecting isn’t what’s actually there.

Finding a way for all parties to collaborate on framing layouts before arriving at the jobsite can ensure everybody gets what they are expecting and that redundancies and excess time and material requirements are eliminated. Planning also should include periodic discussions with suppliers to ensure things like product inventories are in sync.

Because framing waste is both a function of materials and time, consideration might also be given to the cost/benefit of prefabrication and automation for walls, roofs and floors. These techniques reinforce the ‘Plan Ahead’ concept and allow for continuous review and improvement in usage of time and material for builders and contractors that are serious about waste management.

View the Frame As a System

When it comes to reducing waste specifically from framing, you have to look at the product as being part of a system rather than an individual piece. This “system” should naturally entail maximizing the use of materials.

Employ Advanced Framing Practices

Green building advocates have long promoted the practice of advanced framing techniques—including 2x6 studs spaced 24 inches on center—to cut back on the amount of framing lumber required for a job (not to mention the ample energy efficiency benefits). For example, advanced framing headers replace unnecessary wood materials with space for cavity insulation, while ladder junctions at wall intersections cut down on blocking material.

Leverage Technology

Combined with better planning and communication, software technology can help identify the most material-efficient methods for framing each house.

For example, Forte® software, a load-calculating program for sizing joists, beams, posts or studs, identifies solutions for specific field conditions, and can size for spacing, member depth or simply the optimum economical fit. One of the advantages of Forte is that it allows users to compare and contrast engineered wood and commodity lumber side by side to determine which design would be the most appropriate and efficient.

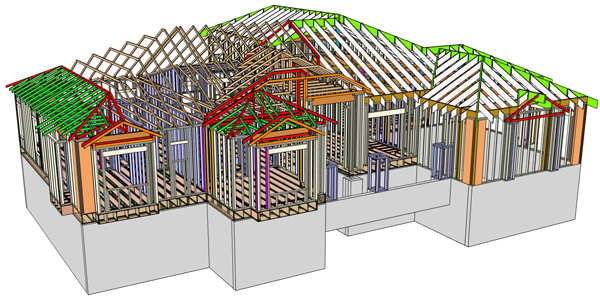

Javelin® software, a design tool (pictured above), allows customers to compose a complete 3D model of the entire structural frame. Part of the design process allows for elimination of redundancies and unnecessary materials, while increasing order and cutting accuracy at the dealer or builder level.

Builders whose suppliers use Weyerhaeuser’s NextPhase® Site Solutions can further rely on precise materials. The tool combines design and fabrication software with cutting equipment to deliver cost-efficient, structurally superior floor framing packages that take any guesswork out of installation and virtually eliminate both material and labor waste.

By combining these and other technologies with a collaborative, systems-based approach, crews can begin to dramatically reduce the amount of wood waste on site.