My tirade on lean production has gone on now for six months. Many who have endured my conference presentations and keynotes of late have suggested I might need stronger blood pressure medication. I get steamed when so many builders pursue actions — I can't call them strategies — that purport to save money but in reality make things worse for themselves as well as their suppliers, trades and customers.

I am not invoking the proverbial consultant crutch that what's happening is bad in the long term. I am talking about now — this quarter, this month, this week. Why do builders pursue actions that lead inexorably to lower margins and upset customers? They understand neither the consequences nor the alternatives.

For last month's column I promised to get into more detail about a different way to preserve and grow margins through lean production methods. First, though, I was compelled to address the incredible proliferation of builder demand letters for across-the-board percentage cuts from their suppliers and trades. That's a perfect demonstration of the primary obstacle to implementing lean methods — the right operating culture.

Let's be frank. If you read my November column and did not see the fallacy of the demand letter approach, go no further. You simply cannot pursue lean production without strong, positive, high-trust relationships with your suppliers and trades. Such relationships and demand letters are mutually exclusive.

If you are still interested, then you either have the strong relationships required or you are convinced you can undue the damage. That's not easy, but I have seen it done.

Getting to the heart of lean productionSo let's look at the heart of lean production and put it in builder-speak.

"Lean" is an extensive body of production science that extends all the way back through management, product planning and purchasing, but at its core it emphasizes eliminating waste in seven ways. These represent huge opportunities for us.

Because our business is almost entirely dependent on suppliers and trades, the waste is harder to see compared to other types of production. A large percentage is buried in the costs the suppliers and trades bear; thus builders simply view this waste as a cost of production. Another big chunk of waste is contained in builder functions, like product development, site development, site supervision and warranty service, which have become accepted as normal costs of doing business.

Here's a quick overview of the seven wastes.

- Over-production. The definition of waste of over-production is producing more than is needed faster than it is needed or before it is needed. In just one year, this has become a monumental industry issue. The current downturn is driven in no small part by excess inventory of finished homes, and a massive finished-lot inventory exacerbates the financial stress. An old mentor of mine used to preach that the greatest builder sin of all was "the unclosed final." I think a lot of home builders would agree with him.

- Wait Time. Defined as any idle time that occurs when two codependent events are not synchronized, this one should need no further explanation. Yet it must, because on any building site you will see houses sitting idle more often than not. Even when there is activity on a job, it's not hard to spot opportunities for simultaneous work. Subtle, but it's wait time all the same. This is also a huge problem in both community start-up and product development.

- Process Waste. This is about redundant effort in production, planning and communication that adds no value to the product or service. For example, I can't tell you how many times I have heard superintendents lament turning in a change request for a plan without working out the recurring problem. Six months later, the superintendent is still short 16 pre-cuts on the Pinnacle II plan. Get a group together and start brainstorming all the mistakes your company makes over and over. You'll get it. The trick is taking action to prevent it.

- Transportation. Any movement of material that doesn't support production is waste. Remember US Build and BuildNet? Those were two high-tech start-ups that blew up in the process of trying to apply new technology to old building industry problems, one of which was the rampant waste in distribution costs. If you don't believe it, walk a few projects and look in the back of the first 10 or 12 panel trucks you see. What you will find is mostly just air. These trucks average less than 20 percent full. The buried costs are astronomical but, as we have seen, "out of sight, out of mind." And little changes.

- Inventory. This definition is critical and counter-intuitive, and it's not what you think. House and lot inventory are covered primarily by over-production. Inventory waste is any supply in excess of materials needed to produce the house in a "just-in-time" manner. In a perfect world, virtually nothing ever sits in a warehouse, on a lot or in a house awaiting installation. It is either being made, being moved or being installed. Our problem is that the cost of this is buried in the balance sheets of our manufacturers, suppliers and trades.

I spent a year in the dark ages of the early '90s on a supply-chain team with a major builder. We were astounded at the amount of waste we discovered buried in processes everyone thought were normal — and the builder pays for every cent of it.

- Motion. Any movement of people that does not contribute to building a home is waste. I am looking for just one builder who finally has the guts to say to their trades, "We will pay you $200 for each and every dry run to our sites." That would get some attention! But you know what would happen? Within 6 months, the builder would see improved margins. Yes, I am saying it would be a money-maker, because the only way a builder could eliminate the cost of dry runs would be to eliminate the causes. A key tenant of lean production is you always stop the line; you never bury a mistake. Or guess what; it never gets fixed. Not confronting production glitches such as wasted trips simply guarantees they will continue — and continue to cost you money.

- Defects. Defect waste, despite an overall improvement in the industry and a few examples of extraordinary performance, is still rampant. The evidence is inarguable and the cost is horrific. Even many of the top-scoring builders on the J.D. Power and Associates survey routinely reserve 10 days to two weeks for rework and repair between "final" and closing. This is 100 percent pure waste and costs far more than the obvious supervision, carry costs and buried trade expense. What's worse: every trade involved in this quality charade performing rework is not building new homes.

- Motion. Any movement of people that does not contribute to building a home is waste. I am looking for just one builder who finally has the guts to say to their trades, "We will pay you $200 for each and every dry run to our sites." That would get some attention! But you know what would happen? Within 6 months, the builder would see improved margins. Yes, I am saying it would be a money-maker, because the only way a builder could eliminate the cost of dry runs would be to eliminate the causes. A key tenant of lean production is you always stop the line; you never bury a mistake. Or guess what; it never gets fixed. Not confronting production glitches such as wasted trips simply guarantees they will continue — and continue to cost you money.

We had 15 glory years in home building, and now come a couple gory ones. That's a good trade-off, all things considered, but the impact is still painful. All of our talk about process improvement has produced scant results. During the boom times, the motivation for builders, suppliers, trades and manufacturers alike was never sufficient. That has all changed now.

Fear is a powerful motivator in the short-run and perhaps enough to wake the industry up. People seem at least willing to listen now and, ironically, they also have the time. You have a choice. You can go the formula route of slashing overheads and hammering your suppliers and trades and ultimately lose more than you gain, or you can take the road less traveled in home building that will show you how to maintain your profits without destroying the margins of your suppliers and trades and trashing the relationships that took years to build. That road is called lean production, and it's wide open — no traffic at all. How about creating some?

| Author Information |

| Scott Sedam is president of TrueNorth Development, a nationwide consulting and training firm focused on quality, process improvement and organizational development. He can be reached at scott@truen.com. |

Advertisement

Related Stories

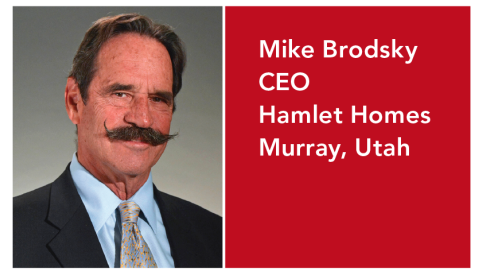

Hamlet Homes' Mike Brodsky on Finding Successors and Letting Go

A transition that involved a national executive search, an employee buyout, and Builder 20 group mentorship to save the deal

Time-Machine Lessons

We ask custom builders: If you could redo your first house or revisit the first years of running your business, what would you do differently?

Back Story: Green Gables Opens Up Every Aspect of its Design/Build Process to Clients

"You never want to get to the next phase and realize somebody's not happy."