The Domino Effect of Idle Time in Construction

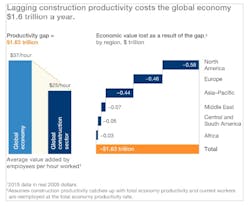

The construction industry is one of the least productive sectors worldwide and costs the global economy 1.6 trillion dollars per year in lost value. By tackling what is commonly known as idle time (aka lost productivity), the astonishing 98% of construction megaprojects worldwide that experience costs overruns of more than 30%, and 77% that are at least 40% late could be something of the past.

Research shows that timely adjustments in technological and operational strategies on construction projects can considerably shift the stark statistics that have plagued the industry for decades with cost overruns, high emissions, and disappointing project delays. But meaningful change starts with understanding "why” it’s important to eliminate idle time.

We will look at why tackling idle time from a technological and operational standpoint is essential.

The domino effect on all operations

Idle time affects the productivity of employees, and equipment that is available (and in good operational state) but are underused. An example of equipment idle time would be trucks waiting in line to be loaded with excavated earth that will be taken from the construction site. If the engine remains on for more than 5 minutes while waiting, a considerable amount of fuel is consumed and wasted. Additionally, the truck driver’s hours represent non-productive hours that still have to be paid. These two examples demonstrate the domino effect of idle time in construction and the importance of capping it by optimizing employee and equipment productivity.

Tackling idle time improves project coordination and risk management

Poor site coordination accounts for 70% of delays and cost overruns. Lack of coordination affects high-level planning, where long-terms project goals and day-to-day onsite activities are involved. The effect is that processes that are prone to bottlenecks are exacerbated, and project risks are increased. For instance, equipment or employees that are idle can congest a construction site and may interfere with normal operations (such as when a construction site access road that is crowded with idle trucks, thus blocking other equipment from entering).

Tackling instances of idle time is necessary to avoid process bottlenecks and mitigates accidents, reduce reworks, and improve project coordination.

Less idle time means lower equipment maintenance costs

Construction maintenance accounts for 10-30% of the total project cost depending on the types of machines used. This applies to both large-scale projects which involve heavy construction (such as large infrastructure projects) and fragmented specialized trades where contractors take care of smaller projects (such as electrical, plumbing, and landscaping).

Whether large or small, when an equipment with an engine operates in the idle phase (running, but not performing any productive work), it cannot attain enough heat to guarantee proper combustion. Consequently, friction due to oil contamination from accumulated deposits can lead to quicker engine wear and tear. More wear and tear means more maintenance work, which racks up both maintenance costs and increases machine downtime.

Key takeaway

Idle time and productivity are interrelated: a project with excessive idle time will fall short of productivity thresholds and will fail to add much value at each phase while racking up costs. Employee and equipment non-productivity are the main areas where idle time occurs, and because of their interdependence, both are directly affected by low productivity.

This domino effect affects the service life of the equipment and the need for frequent maintenance. It also affects the human capital onsite by creating an underperforming work environment. The result is projects that are often late and where budgeted costs are superseded while eroding project profits and efficiency.