This article first appeared in the May/June 2025 issue of Pro Builder.

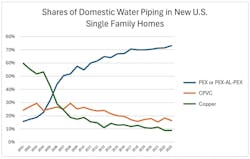

Cross-linked polyethylene (or PEX) has become the go-to piping for residential water delivery systems, providing a cost-effective, dependable alternative to copper and chlorinated polyvinyl chloride (CPVC) pipe. PEX plumbing is a popular choice in new construction because it offers flexibility and corrosion resistance, and it’s easy to install. In fact, the Annual Builder Practices Survey conducted by Home Innovation Research Labs has tracked the trajectory of PEX tubing’s popularity among home builders. PEX piping now commands more than a 70% share of the new-home market, while CPVC and copper pipe have dipped below 20% and 10% market share, respectively.

What Is PEX and What Are Its Advantages?

PEX pipe starts as high-density polyethylene (HDPE) and through either a chemical or physical process its molecular structure is modified to create cross-linking that results in a stronger bond between the polymer chains. The result delivers the following advantages:

- Increased durability: The cross-linking process strengthens the polymer structure, making it more resistant to cracking and impact.

- Higher temperature resistance: PEX can handle temperatures up to 200° F (93° C), making it suitable for hot water applications.

- Flexibility: Unlike rigid pipe such as CPVC or copper, PEX tubing is flexible and can be bent without breaking, which reduces the number of fittings (and thus labor and materials) needed. Still, some types of PEX are more flexible than others.

- Improved chemical resistance: PEX pipe resists chlorine, scaling, and corrosion.

- Memory effect: Some types, such as PEX-A, have "shape memory" that allows the material to return to its original shape after temporary expansion caused by heated water.

The Different Types of PEX

There are three kinds of PEX piping on the market: PEX-A, PEX-B, and PEX-C. Each has its own advantages and disadvantages. PEX-A and -B are the most used by far, so we’ll focus on them here.

PEX Installation Tips

The following best practices apply to both PEX-A and PEX-B pipe:

- Use a PEX-specific pipe cutter to make clean, straight cuts

- Make sure fittings are spaced far enough apart, per manufacturer guidelines

- Use multiport tees (main photo) and 90-degree elbows (photo, below) to greatly decrease the number of fittings needed

- Ensure pipe supports are installed at the spacing recommended by manufacturer guidelines

- Minimize exposure to UV light. PEX degrades if exposed to sunlight for long periods of time

What Is PEX-A?

PEX-A is manufactured using the “Engel method,” which mixes peroxide into the polyethylene before the forming process (extrusion). At high temperatures, the peroxide decomposes to initiate cross-linking between polymer chains. The tubing is then melted and extruded at around 390° F to 480° F.

As the extruded tube cools, the cross-linking reaction continues, creating a three-dimensional polymer network that gives PEX-A enhanced durability and flexibility.

This is the type of piping manufactured by brands such as Uponor, Rehau, and SharkBite, among others.

What Are the Advantages of PEX-A?

Compared with PEX-B and PEX-C, the Engel process creates a higher amount of cross-linking (70% to 85%) within the material, which results in:

- Superior flexibility

- More uniform cross-linking: PEX-A is less prone to weak spots or inconsistencies

- Superior shape memory. If PEX-A is bent too far and kinked, it usually can be repaired or reshaped using heat.

- Increased resistance to stress, pressure, and chemical exposure

- No need for continual calibration of expansion tools

- Consistent inner diameter, even after expansion to accommodate fittings, ensuring full water flow

What Are the Disadvantages of PEX-A?

PEX-A pipe costs more than PEX-B and PEX-C.

Tips for Installing PEX-A Pipe

- Expand the pipe end using an expansion tool and the correct size of expansion ring. Rotate the tool slightly after each expansion to ensure an even stretch around the circumference of the pipe.

- Be sure to follow the recommended number of expansions per pipe size. If the connection slides into the PEX with no friction, this can be a sign of over-expansion.

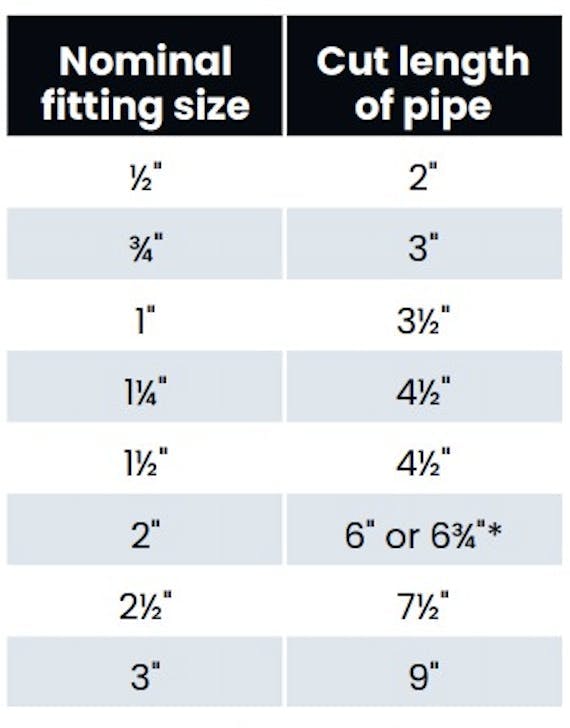

- Make sure fittings are spaced far enough apart, per manufacturer guidelines. For example, if ½-inch piping is being used, there must be at least 2 inches between fittings. (See the table, below, for a full list of spacing guidelines.)

- Bends cannot exceed six times the outside diameter of the pipe.

- Avoid kinking the pipe. While PEX-A tubing can usually be re-rounded using heat, excessive kinking weakens the material.

- PEX-A naturally tightens around the fitting, eliminating crimping or clamping.

- Ensure fittings are fully seated into the pipe with the shoulder of the fitting in contact with the pipe and expansion rings.

- Avoid using metal clamps or nails, which can damage or puncture the pipe.

What Is PEX-B?

PEX-B is manufactured through the use of the “silane method” in which high-density polyethylene is melted and mixed with a silane-based compound to serve as a cross-linking agent. (Silane is used in many industries. It is a colorless, flammable gas made up of silicon and hydrogen atoms.)

The molten polyethylene with silane is shaped into pipes through an extrusion die and is cooled to maintain its form. The extruded pipe is exposed to water (a hot water bath or steam) or is kept in a humid environment, which triggers a chemical reaction that causes cross-linking between the polymer chains. The result is 65% to 70% cross-linking throughout the material.

Manufacturers that offer PEX-B piping include Viega, SharkBite, Apollo, and NIBCO, among others.

What Are the Advantages of PEX-B?

- More affordable than PEX-A

- Easier installation than copper piping

- Increased flexibility compared with copper and CPVC

- Increased resistance to chemicals and scaling compared with copper

- More resistant to freezing than both copper and CPVC, as it can expand slightly without cracking

- Stronger resistance to chlorine and oxidation, making it suitable for areas that have high chlorine content in the water

Wht Are the Disadvantages of PEX-B?

- Less flexible than PEX-A pipe

- Less shape memory compared with PEX-A. For example, if PEX-B tubing is kinked, the damaged area can’t be repaired with heat

- Tool for installing the crimp fittings must be calibrated regularly to ensure proper installation

- Slightly reducing the pipe’s diameter at fitting locations can hinder water flow

- PEX-B fittings require more force than PEX-A

- More difficult to install in tight spaces

Installation Tips for PEX-B Tubing With Crimp-Style Connections

- Typically, crimp or clamp (cinch) fittings are used to connect sections of PEX-B pipe. If you see expansion fittings being used, verify that with the manufacturer guidelines immediately

- PEX-B fittings require specialty crimp tools, with most of them recommending calibration at least daily

- Use a crimp gauge to ensure proper sealing

- Any bends must not exceed eight times the outside diameter of the pipe. For example, a ½-inch-diameter PEX-B pipe allows a minimum 4-inch bend radius

- If kinking occurs, cut out the damaged section and use a coupling fitting

Given all of the advantages that PEX offers, it’s easy to see why this material has become the water piping of choice for builders and plumbers across the country.

About the Author

Andrew Shipp

Andrew Shipp drives quality and innovation in homebuilding as a building performance coach and client relations manager at IBACOS.