Improving Process With Clarity, Priority, and Focus

Among the most frustrating work requirements, whether in business, education, volunteering, or any other endeavor, is how to prioritize the myriad things that cry out to be done. Serious endeavors in process improvement are no different, as you typically uncover a long list of product and process issues to resolve—and all should have been done yesterday.

There are as many reasons for failure as there are things to do, but the top cause is simply trying to fix too many things at once. Can I get a witness? No trouble there.

The most common approach to solving the prioritization challenge is found in divining what the boss wants. That won’t guarantee that you will pick the right things to help the business, but it won’t get you fired. Some people turn boss-pleasing into an art form and make a career out of it while the company just muddles on.

At least as common is choosing by committee. The rub there: More often than not, no one feels truly responsible for the decision. I recall the East Coast operation of a major home builder whose team members all voted to back a project, moving it to the front burner because the builder could do “five units per month.” After the project tanked, each team member privately revealed that he thought the builder could do no more than three units monthly, at the most. Groupthink wins again.

Or you can pick what you find personally compelling. I like that to the degree it generates commitment for going after a project and seeing it through—as long as you are sure your personal passion is aligned with the company’s goals.

In the end though, many management teams are so overwhelmed that everyone runs off to their corner of the business and tries to implement individual improvement efforts with little consideration for the impact on others. That’s operating in silos and it’s rare that anything good comes of it. We need something better, but what?

When asked who has influenced me the most in business—beyond the many great mentors I’ve had in home building—I often cite W. Edwards Deming and Eli Goldratt. Deming gets at least a look of recognition from many, but Goldratt, rarely a nod. That’s unfortunate because the heart of Goldratt’s operating philosophy is simpler and easier to apply than Deming’s.

Goldratt's Theory of Constraints

Just as with Deming’s “14 Points,” you can spend years studying the nuances of Goldratt’s Theory of Constraints (also known as TOC), and I asked Fletcher Groves, an industry consultant who has studied Goldratt more than anyone I know, to write the accompanying “A Deeper Dive” sidebar.

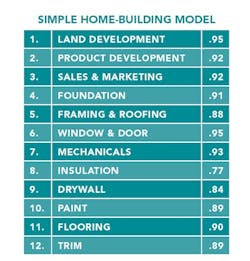

The principle at the heart of Goldratt’s work, however, can be taught in 10 minutes. We’ll employ a simplified 12-step model of home building process and productivity ratings for each element. These ratings are for Alpha Homes; yours will be different.

Let’s say we just finished a big planning session and have a list of five or seven things to improve in each element totaling 75 improvement ideas. Everyone’s got plenty to do, so just get cracking, right? Not so fast. The lowest productivity rating, in this case step #8 on the list (Insulation), is what Goldratt calls the “constraint,” aka the bottleneck, roadblock, obstacle, etc. So we attack that one, but plenty of others need help, so our urge is to start improving those as well.

But consider what happens when we do. If we increase the productivity or capacity of any of the first seven elements, sitting at the end of step #7, Mechanicals, is a pile of inventory in the form of work-in-process (WIP), and it just keeps backing up. Inventory costs erode profit while we wait for step #8, Insulation, to catch up. In fact, we can raise the productivity of all seven steps prior to Insulation to 1.00, but if Insulation stays at .77 we won’t get a single additional house out the back end and our costs will balloon. A very simple concept, but rarely understood or applied.

Focus Efforts on Greatest Constraint

Consider now the result if we increase the productivity of #9 through #12, starting with Drywall. The result is excess capacity and no additional units being produced. Unused capacity costs money as well. A Goldratt purist will thus state that it’s a complete waste to put any time or effort into anything except your primary constraint in the system. Focus there, and results will improve much faster at a lower cost.

So let’s say we did exactly that, opened up the Insulation constraint from .77 to .90 for productivity. Now what? Simply go to our next constraint, which in this example is step #9, Drywall at .84. Fix that and next on the list is Framing & Roofing at .88, and so on. It never ends because by the time we get everything up to the level of our most productive element, something else will have become the most limiting constraint. In time, it could happen that we run short of lots, so Land, formerly #1, has now become our greatest constraint. Currently, a safe guess is that the greatest constraint for most builders is framing labor.

How simple is this? Find your greatest constraint and focus the majority of your efforts on that. Alpha Homes has 75 improvement ideas for its building process, but let’s first solve all those related to step #8, Insulation. In reality, it’s rare that everyone in the company can work on the single greatest obstacle, so you may make some efforts on others, but keep the focus on the biggest roadblock. And of course, it gets more complicated than this simplified example.

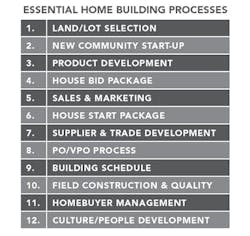

Take a look again at the The 12 Processes for Sustainable Profit we previously identified:

First, as Fletcher Groves describes in “A Deeper Dive,” you may find a constraint that has its roots in more than one process. Beta Homes was working on about 15 different initiatives this year, improving everything, everywhere, with the primary result being frustration. The company did its homework and discovered that the single biggest constraint is keeping up with the details and paperwork required to process Beta’s considerable options and selections list. Purchasing and estimating are buried doing costing and change requests, design can’t keep up with the plan detail revisions, the field superintendents aren’t sure what they’re building, POs are inaccurate, VPOs are way up, the schedule is slipping, all while suppliers and trades are bending under delays, rework, and extra trips. And right there we touched half of the processes listed above!

Bottlenecks Revealed

Now take that constraint, process map it, break it down further, and soon you’ll reveal the greatest bottleneck within the first constraint you identified. You now have a place to start. Perhaps that software you were about to buy answers the question by enabling better POs and VPOs, but maybe the real constraint is in your “anything goes” product development mentality and you need to focus on simplification. Or it could be that your practice of never giving purchasing the two things it needs to do its job—final product specifications, and enough time to create solid bid packages and secure contracts with detailed scopes of work—is actually the primary constraint. Or is it sales and its complete lack of discipline in selling what you can profitably build? This is your job now, to employ the tools available to identify the true constraints, get to the heart of them, solve the current problems, and prevent new ones going forward. The result is profit, and that’s your goal.

It’s an old trick question of mine to ask a group, “What’s the purpose of a business?” The immediate brain-jerk reaction is: “To make a profit!” To which I immediately respond, “Wrong!” After allowing the group to gaze around befuddled for a few moments, I advise that the goal of a business is, indeed, to make money. The purpose, however, has to be established in the eyes of the customers you are serving, without which there is no business. The purpose is to fulfill a customer need. Said another way: The purpose is to solve and prevent problems. Do this well and you meet your goal—to make money. Semantics? No, because I’ve observed a clear difference over the years between those companies focused merely on the goal, rather than on the purpose. Be clear though. If you do not consistently achieve the goal of making money, you will soon be out of the business of solving problems for your customers. There’s no better method than Goldratt’s Theory of Constraints to enable your pursuit of that goal.

Goldratt’s Theory of Constraints: A Deeper Dive

By Fletcher Groves

Just because builders employing TrueNorth’s 12 Essential Processes find so much that needs improvement, doesn’t mean the effort can start just anywhere, and certainly not all at once. The most focused method of continual improvement is found in the Theory of Constraints (TOC), the methodology that grew out of The Goal: A Process of Ongoing Improvement, the first of Eli Goldratt’s four business novels. TOC originated with The Goal, but it now extends far beyond the storyline of synchronous manufacturing production flow and the stated goal of “making money, both now and in the future.”

To put Goldratt’s Theory of Constraints in perspective, Lean works like an antibiotic fighting infection, attacking waste wherever it is found. Six Sigma emphasizes reduction of variation, which may or may not produce waste. Total Quality Management treats waste as a side issue to quality. TOC, however, views everything as part of the overall system, including workflow, production problems, variation, waste, resources, schedules, work-in-process—all from the perspective of the system constraint: whatever limits the system’s ability to achieve its goal.

TOC is systems-thinking that’s based on cause-and-effect relationships, interdependent parts of a whole, and ordered behavior of the business environment. It is rooted in the way things work, how problems are solved, and how constraints are managed. Home building companies are not loosely connected sets of independent parts—collections of processes, departments, systems, resources, and policies. They are systems of interdependent elements that must work together to accomplish the goal. Theory of Constraints recognizes that builders don’t operate with unlimited capacity, resources, capital, or opportunities. TOC insists that improvement efforts be prioritized and that some problems and opportunities will have to wait until other constraints are addressed. Like the weakest link in a chain, there is always a constraint that limits the current performance of a system. Efforts to improve anything other than the primary constraint will not just be unproductive, they may make things worse.

How does a builder use TOC principles to systematically attack waste found in TrueNorth’s 12 Processes?

1 Home building production is project portfolio management. The 12 processes are embedded elements to support the overall system and are thus subordinate to the system.

2 TOC cause-and-effect logic tools such as current and future reality trees, link visible symptoms of problems to their root causes. Root causes may be found in more than one process, a nuance that can be obscured with focus on individual processes alone.

3 Similar to the iterative 5 Whys technique of Lean Production, the builder relentlessly challenges cause-and-effect assumptions, prioritizing improvement efforts around true constraints.

4 Apply appropriate tools to address the constraint, without regard for the “improvement theology” origin, be it Lean, Six Sigma, TQM, business process methods (BPI-BPM-BPR), or TOC.

5 Map the 12 Processes, and with insight from understanding root cause, document their current (as-is) states, identifying all waste and non-value-added work.

6 Redesign each process to meet the desired future (should be) state and prevent errors, waste, mistakes, rework, redundancy, needless paperwork, cost, and lost revenue.

7 Document the future (should be) state of the 12 Processes so the newest, least experienced teammate can self-learn the requirements of his/her position, understanding its relationship to every other position involved in the process.

8 Through team-based performance compensation, create a sense of urgency for generating results—an urgency toward achieving the levels of operating performance in these processes that generate better economic outcomes.

—Fletcher Groves is president of SAI Consulting.

About the Author

Scott Sedam

Scott Sedam is president of TrueNorth Development, a consulting and training firm that works with builders to improve products, process, and profits. A senior contributing editor to Pro Builder, Scott writes about all aspects of the home building business and won the 2015 Jesse H. Neal Award, business journalism's most prestigious prize, for his commentary in Pro Builder. Scott invites you to join TrueNorth's Lean Building Group on LinkedIn and welcomes your feedback at [email protected] or 248.446.1275.