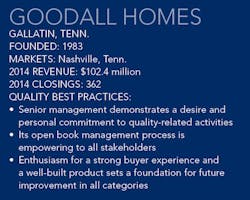

NHQ Silver Award Winner: Goodall Homes

Why pay a consultant to improve your business when you can do it yourself? Because most builders are so busy that they won’t work on their internal strategy and processes unless they’re forced to do so, says Keith Porterfield, chief operating officer of Goodall Homes, in Gallatin, Tenn.

Even a company like Goodall, which for years has regularly scrutinized its operations and has even invited critiques from outsiders, such as its Builder 20 comrades, can still find a surprise upon going through the NHQ Awards application process. The private builder was more than ready to take on the application and site visit, having long been a practitioner of quality management exercises such as open book management to align employee goals with company strategy. The November before starting the NHQ application, senior managers completed their annual retreat where they gather off site to establish the company’s “rocks” or long-term goals for the next year. They returned with a load of rocks. But then something changed.

“This problem had been flashing its head at us,” Porterfield says, “but until we stepped back and into the NHQ process, it just didn’t hit us hard enough to pursue it.”

The problem involved having two separate punch lists. For years, Goodall had delivered its homes by sending its quality control department to inspect the house two weeks before closing. The inspectors create a list of defects, hand the list to the project manager and the trades, who then have a week to complete the fixes. A week before close, the customers visit for their new-home orientation, and another list of fixes is generated. The painters and drywallers would then make a second trip to the house to take care of those.

But what if trades made just one trip? The potential for saving time and money, particularly when availability of trades is tight, was alluring. “We figured that if we intend to build 450 homes this year, that’s 450 extra trips by the painters and drywallers,” Porterfield says. “That’s 450 extra lists our project manager is running. This is a pretty big rock, but if we drop all the other rocks that we haven’t started on yet and focus all of our energy on this one, we figured we could accomplish this by October 1.”

The trades still get a to-do list two weeks before close, but now they have 10 days to finish. All of the defects are taken care of and the homeowners come at closing for the orientation visit but no list is generated. A lot of steps, process development, and coordination with subcontractors had to occur to cut the list in half and still produce a house with no defects that would make the homeowner happy.

“The hardest thing about improvement is that you have to look at yourself objectively,” Porterfield says. “When somebody points out something you think you can do better, there are two basic responses: You can get defensive, or you can listen and be objective about it. If you don’t have that [listening] culture, then it really is an uphill battle.”

Goodall Homes' Rizer Point