How to Frame Walls That Combat Moisture

The housing industry has come a long way toward improving the thermal efficiency of wood-framed wall assemblies by using new and better insulation and air-sealing products, weather-resistant barriers, and building practices.

But as increasingly stringent energy codes require higher-performance building envelopes, issues of trapped moisture developing in tight, well-insulated wall assemblies can lead to a host of problems for builders and homebuyers.

That concern dovetails with builder complaints about the premium cost to purchase and properly install continuous exterior wall insulation (for example, foam panels), a proven solution that adds thermal resistance to the envelope, drastically reduces thermal bridging, and minimizes air infiltration.

To better understand those and other building-science–related issues, the Department of Energy’s Building Technologies Office (BTO) supports a significant number of real-world research and field testing of projects through its Building America program, including the two conducted by Home Innovation Research Labs, a market research, product testing, and accredited third-party certification agency in Upper Marlboro, Md.

A Next-Gen Wall Assembly

Leveraging BTO funding, Home Innovation took on the challenge to field test and lab test a new perimeter wall assembly that makes it easier and less costly for builders to benefit from continuous exterior insulation.

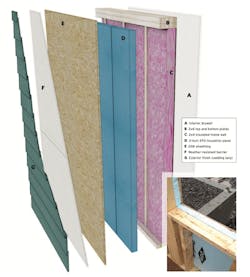

The Extended Plate and Beam Wall System (EP&B) is a remarkably simple yet measurably more effective, buildable, and cost-efficient R-23 or higher assembly. Even better, EP&B’s use of conventional wood-framed, high-R wall materials—albeit assembled in a slightly different sequence—make the system adaptable to both site-built construction and factory panelization.

Here’s how it works: Standard 2x4 studs are installed flush to the inside edges of 2x6 bottom and top plates, leaving a 2-inch space to the exterior. Continuous 2-inch rigid foam insulation is fastened and joint-taped directly against the exterior face of the studs, resting on top of the extended bottom plate and tight to the underside of the extended top plate; structural sheathing is then installed over that insulation layer, but is attached directly to the face of the extended top and bottom plates, as well as through the insulation along the stud lengths (see illustration, below).

This sequence, with the studs and structural sheathing sandwiching the rigid foam insulation, provides a drainage plane surface for a separate weather-resistant barrier over the sheathing, more rigid support for windows and doors, and a solid, structural nailing surface for finish claddings, instead of furring strips attached to or embedded in the insulation panel. Also, in an off-site panelized scenario, the sequence of materials better protects the wall assembly from damage during transport to the jobsite.

Real-World Results: Testing the Wall Assembly

To test the wall in the real world (in addition to lab tests and computer simulations), Home Innovation partnered with Michigan builder McIntyre Builders, and its framing contractor, Kevin L. Smith Construction, to build two test homes in Grand Rapids, Mich., in the heart of climate zone 5a, a narrow band from Nebraska to New York per the map of U.S. Climate Zones set by the IECC (International Energy Conservation Code).

The EP&B walls for those homes used extruded polystyrene (XPS) as the continuous rigid foam insulation material and a 1-inch-thick layer of closed-cell spray foam and blown fiberglass to insulate the 2x4 wall cavities.

A full year of monitoring the two occupied homes, along with computer simulations of heat and moisture transfer in several other areas across the country, verified the long-term moisture performance of the EP&B wall assembly. Specifically, the average peak wood moisture content within the walls was less than 15%—well below accepted levels of risk—and the relative humidity readings in the EP&B wall cavities never breached 80%, averaging between 40% and 60%, which is comparable to normal interior ambient conditions.

The EP&B assembly also meets or exceeds International Residential Code prescriptive requirements for vertical loading and shear performance, as well as the most stringent prescriptive insulation requirements for above-grade walls in all IECC climate zones. And to assure builders about the assembly’s cost compared with more common approaches, Home Innovation priced out the EP&B wall at $21.12 per square foot, about 50 cents per foot less than a conventionally sequenced 2x4 wall with continuous insulation achieving the same R-value.

RELATED

- For Better Indoor Air Quality: Build Tight and Ventilate Right

- Building Envelope Solutions for Moisture Management

Addressing Moisture in Wood-Frame Wall Assemblies

In a separate study, Home Innovation Research Labs sought to monitor moisture performance of thermally resistant (high R-value) walls in newly built and occupied homes across the country. Researchers selected 22 homes with different wood-framed wall assemblies in IECC climate zones 4 through 7 (roughly the mid-to-northern half of the country), specifically where moisture vapor driven from the home’s interior (aka “vapor drive”) is substantial in winter.

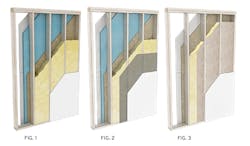

Researchers considered three categories of wood-frame wall assemblies: those with continuous insulation and no vapor retarder (Fig. 1, below); those with continuous insulation and an interior vapor retarder (Fig. 2, below); and those with various types of vapor retarders and no continuous insulation (Fig. 3, below).

The walls studied used 2x4, 2x6, or 2x8 framing, and either plywood, oriented strand board, or the Zip system from Huber Engineered Woods, which integrates a weather-resistant barrier to the exterior face of an OSB sheathing panel. All walls included full cavity insulation; assemblies with continuous exterior insulation over the sheathing used 2-inch thick panels.

Researchers attached sensors to the structural sheathing, wall studs, and rim joists to measure temperature, relative humidity, and moisture content in the finished walls just before and during occupancy.

Test Wall Results

During several months of monitoring, most of the walls showed moisture content levels that would not saturate the fibers of their various wood-framing components, either during winter infiltration or as the components dried in the spring.

Specifically, the study verified the value of continuous exterior insulation to mitigate the forces of vapor drive and, perhaps more importantly, its capacity to dry out incidental moisture.

Similarly, walls with a standard polyethylene vapor retarder placed on the inside face of the wall studs (a practice to be avoided in hot/humid climates), also showed low moisture content levels, regardless of exterior sheathing or finish cladding materials.

Wall Assemblies: What to Avoid

On the other hand, and specifically in climate zone 5a (roughly along the upper Midwest), walls insulated with damp-sprayed cellulose and without an interior vapor retarder or exterior insulation experienced large seasonal moisture fluctuations, a condition made worse with deeper wall cavities or with impermeable cladding and interior finishes.

Similarly, in climate zones 4a and 4c, walls without exterior insulation or an interior vapor retarder experienced substantial seasonal moisture fluctuations.

And, at a house in New York, the use of open-cell spray-foam cavity insulation (instead of the closed-cell variety specified), resulted in moisture content levels that neared saturation of the OSB sheathing fibers, underscoring the difference in vapor permeability between those two spray-foam insulation materials.

Lena Burkett is a Building Science Research Engineer, at the National Renewable Energy Laboratory (NREL) in Washington, D.C., with a focus on residential energy-efficiency research.

Access a PDF of this article in Pro Builder's April 2020 digital edition