Like all wood products, glued laminated timbers (glulam) may undergo expansion and contraction as their moisture content stabilizes. As a result, glulam beams may develop seasoning checks (small cracks at board ends). The degree of checking that might occur depends on the combined effects of initial moisture content, seasonal conditions, handling and storage practices, and the in-service environment after installation, and also may be influenced by the rate at which the glulam member moisture content changes from its level at the time of manufacture to its expected in-service level.

RELATED

- What to Select? Wood vs. Engineered Lumber For years, builders have used traditional lumber to build homes, but ever since engineered lumber came into the picture, builders have been left wondering, Which one do I use for my projects?

- Engineered lumber practices and projects blogs on probuilder.com

Take These Steps to Minimize Seasoning Checks

When checks do occur, they are primarily an aesthetic concern and can be filled with an elastomeric filler to improve appearance. Still, there are steps builders can take to limit how much seasoning checking occurs:

- Do not unwrap and expose members to the elements in early summer, because rapid change in glulam moisture content is likely as the season progresses.

- In arid climates, avoid direct exposure of unwrapped members to the effects of the sun and wind.

- Avoid direct exposure of unwrapped members during storage or after installation.

- Do not store on site without protection or unwrap prior to installation.

- Limit member exposure to weather conditions prior to building enclosure.

- Cover and protect member after installation.

- Avoid rapid changes in temperatures that can affect the rate of drying during the first full heating cycle.

- Avoid direct exposure of glulam to heating outlets.

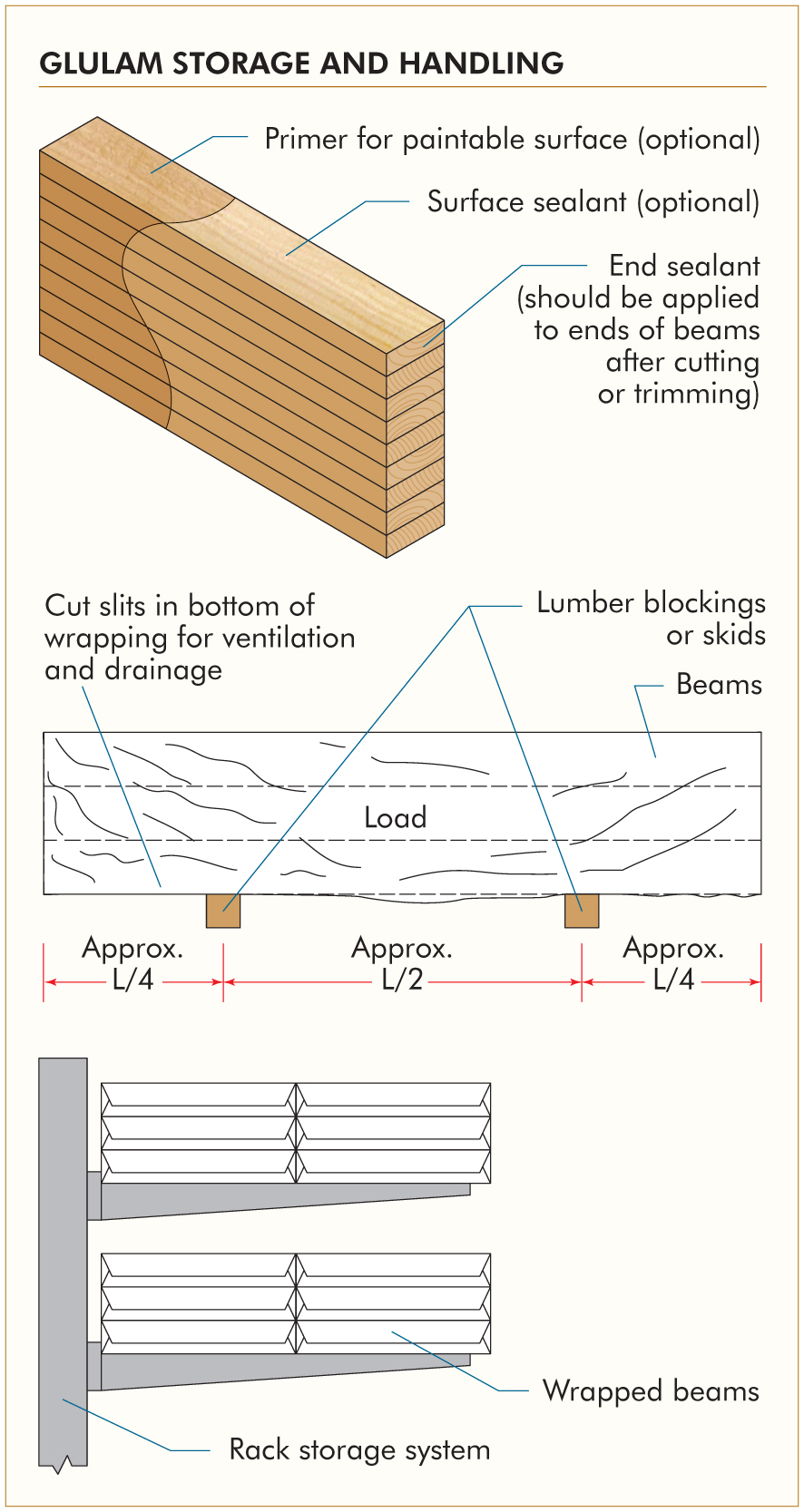

- Cut slits in the underside of the wrapping paper to guard against water “ponding” inside the wrap during jobsite storage.

- Avoid rapid changes in seasoning rate by construction scheduling and control of building's interior environmental conditions.

- Apply end sealer when the glulam beam is cut to length at a distribution yard or jobsite. Remove wrapping after installation in enclosed space where members are allowed to stabilize naturally during construction.

- Wrap members and store them well off the ground with secondary cover.

Glulam manufacturers can't assure that seasoning checks will not occur in individual glulam members as the result of handling and storage at distribution facilities, jobsite storage, installation, and regional climatic conditions. To reduce the possibility and severity of checking, it's important to coordinate delivery schedules to minimize jobsite storage. Guard against direct exposure of glulam members to severe conditions like high temperatures, rain, wind, and other damaging weather conditions. Hot/dry and wet/winter climates can both create high-risk environments, depending on how quickly the moisture content is lowered. If high-risk conditions cannot be avoided, take extra precautions in storage and installation to protect the beams and columns.

This how-to article is part of the Builder Tips series of publications from APA-The Engineered Wood Association. View more helpful strategies, here.

Advertisement

Related Stories

Quality Matters

5 Ways to Silence Squeaky Floors

Take these tips to heart to deliver quiet floors and satisfied homeowners

Quality Matters

Tips for Placing HVAC Ducts in Conditioned Space

See how putting HVAC ducts inside conditioned space in a home benefits both the builder and the homeowner

Quality Matters

Don't Underestimate the Importance of Roofing Underlayment

Regardless of which product you choose to use, installing a roofing underlayment will help ensure the roof system withstands the elements and the home stays dry